Sheet metal fabrication

Rapid-MFG is up to the task whether your company needs mass-produced sheet metal fabrication parts or one-off sheet metal fabrication parts.

Custom Sheet Metal Fabrication Services - Rapid-MFG

Founded in 2002, Rapid-MFG has served many industries requiring world-class metalworking, including fabrication, metal forming, stamping, welding, and more. Our high-quality metal fabrication and engineering services provide industries with the tools and resources to stand out in their respective fields. Our extensive experience allows us to complete any metal fabrication project. We provide high-value custom sheet metal components to a wide range of industries. Examples include transportation, waste management, military and government, mining, food service and sanitation, mechanical, architectural and construction, institutional/recreational, pharmaceutical, general industry, agriculture, startup startups, and more.

Rapid-MFG’s state-of-the-art 10,000+ square meter facility provides innovative solutions, profitable results, and a high level of performance and quality that exceeds expectations for customers worldwide.

- Lead time from 5 days

- From 1 to 10,000+ parts

- Wide range of processes available

- ISO and IATF certified

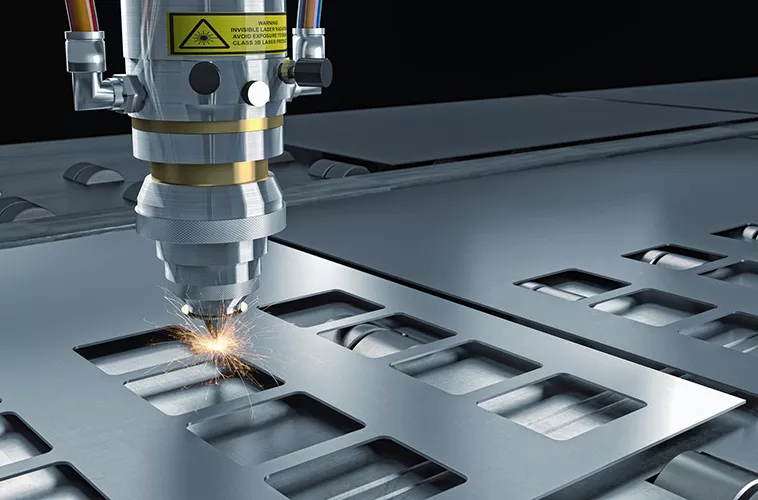

Laser Cutting

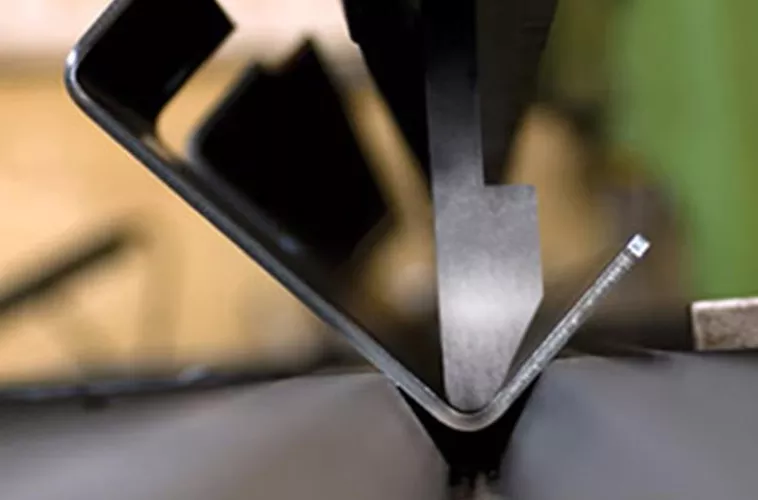

Sheet Metal Bending

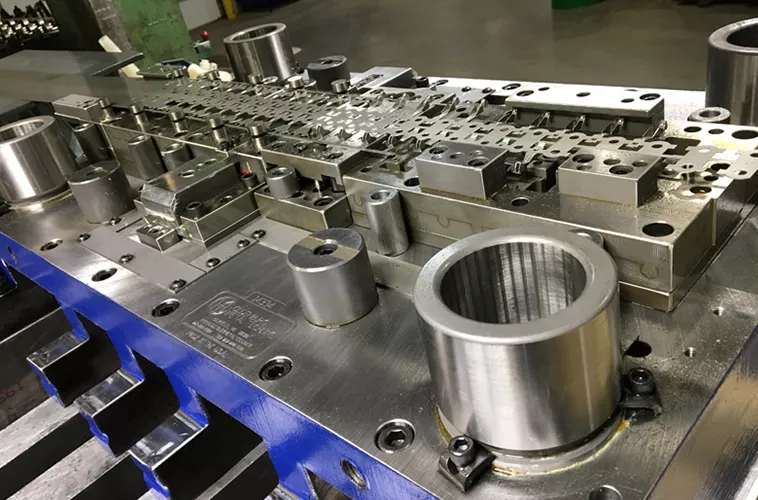

Stamping

Welding

Sheet Metal Prototyping and Production Services

We can help you fabricate your enclosures, brackets, assemblies, weldments, enclosures, housings, and other sheet metal parts and prototypes quickly and accurately. Our rapid sheet metal prototyping and production services include various tools, hand-manufacturing techniques, and processes that allow us to realize some highly complex parts.

Applications and Advantages of Sheet Metal Fabrication:

- Fast, Instant Online Quote

- Rapid Tooling

- Quick Prototypes

- Lead times starting at 3 days

- No minimum order quantities

- Volume-based discounts

FREE INSTANT QUOTE

1. Upload Files (Up to 30 at a time)

2. Select Material, Color, Finish, and Quantity

3. Add to order, select shipping, expedite, & purchase

Sheet Metal Design Guidelines and Tolerances

| Minimum Bend: | 1 Times Sheet Metal Thickness |

| Minimum Hole to Edge Distance: | 2 Times Sheet Metal Thickness |

| Minimum Hole to Hole Distance: | 6 Times Sheet Metal Thickness |

| Minimum Bend Edge to Hole Distance: | 6 Times Sheet Metal Thickness |

| Minimum Feature to Countersink Distance: | 8 Times Sheet Metal Thickness |

| Minimum Countersink Depth: | 1 Times Sheet Metal Thickness |

| Relief Cuts: | 1 Times Sheet Metal Thickness |

| Cutting Feature: | ± .00787’’ (0.2 mm) |

| Bend Angle: | ± 1.0° |

| Bend to Edge: | +/- 0.010” (0.254mm) |

Common Sheet Metal Materials

| Material | Ductility | Machinability | Weldability | Corrosion Resistance | Tensile strength | Price |

|---|---|---|---|---|---|---|

| Aluminium-5052 | 7% ~ 27% | Poor | Moderate | Good | 195 ~ 290 MPa | $ |

| Aluminium-5754 | 10% ~ 15% | Moderate | Good | Good | 160 ~ 200 MPa | $ |

| Stainless Steel-304 | 45% ~ 60% | Good | Good | Moderate | 480 ~ 620 MPa | $ |

| Stainless Steel-316L | 30% ~ 50 % | Moderate | Good | Good | 480 ~ 620 MPa | $ |

| Mild Steel-1018 | 17% ~ 27% | Moderate | Good | Poor | 190 ~ 440 MPa | $ |

| Copper-110 | 15% ~ 50% | Poor | Moderate | Moderate | 220 ~ 230 MPa | $ |

Typical Sheet Metal Finishes

| Applicable Materials | Colour | Description | |

|---|---|---|---|

| Bead Blasting | All metals | Uniform matte of raw material colour | Bead blasting is used mainly for visual purposes and comes in several different grits which indicate the size of the bombarding pellets. |

| Powder Coating | All metals | Black, white | Powder coating is typically used because it has a longer lasting, tougher finish than painting. |

| Anodizing | All metals | Clear, black, grey, red, blue, gold | Anodising is used to increase surface hardness, wear resistance and durability of metals such as Aluminium. |

Rapid Sheet Metal Prototyping

We understand the needs of engineers and industrial designers. With full in-house capabilities – bending, laser cutting, welding, as well as CNC folding, tapping, countersinking, counterboring and other processes – we offer unrivalled turnaround on one-off metal prototypes.

Bespoke Production Parts

We have the experience to produce both simple and complex sheet metal parts for the automotive, aerospace, electronics and many more industries. With no Minimum Order Quantity (MOQ), we provide the flexibility and scalable capacity that your project requires.

Our Sheet Metal Fabrication for Various Applications

Whether it’s metallic auto parts or electronic device components, Rapid-MFG’s sheet metal fabrication has helped businesses in different industries.

Automation&Robotic

Image Accordion Content Goes Here! Click edit button to change this text.

Start Your Project With A Free Quote

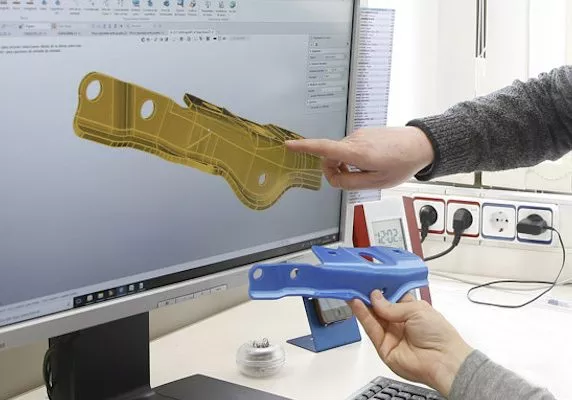

When you upload your CAD files to our prompt quoting system to get a production mold quote, you’ll receive more than just a fast, accurate price and project delivery time. Upon your request, Rapid-MFG will also perform a comprehensive manufacturing design review.

Our engineering team will analyze every aspect of your drawing and identify any areas that should be modified to improve product quality and tool performance while minimizing cycle time.

Explore Related Resources

Advanced experience of German machine tools

Germany has long been recognized as a leading global producer of machine tools brought out by a combination of strong engineering

Large CNC Lathe Machining

Big bore CNC lathe is essential when manufacturing robust large parts and over size parts for a variety of applications which range from aerospace industry to equipment manufacturing.

Judging the accuracy of a CNC machining center

In the current environment in manufacturing, accuracy and precision in CNC machining centers are valuable commodities.