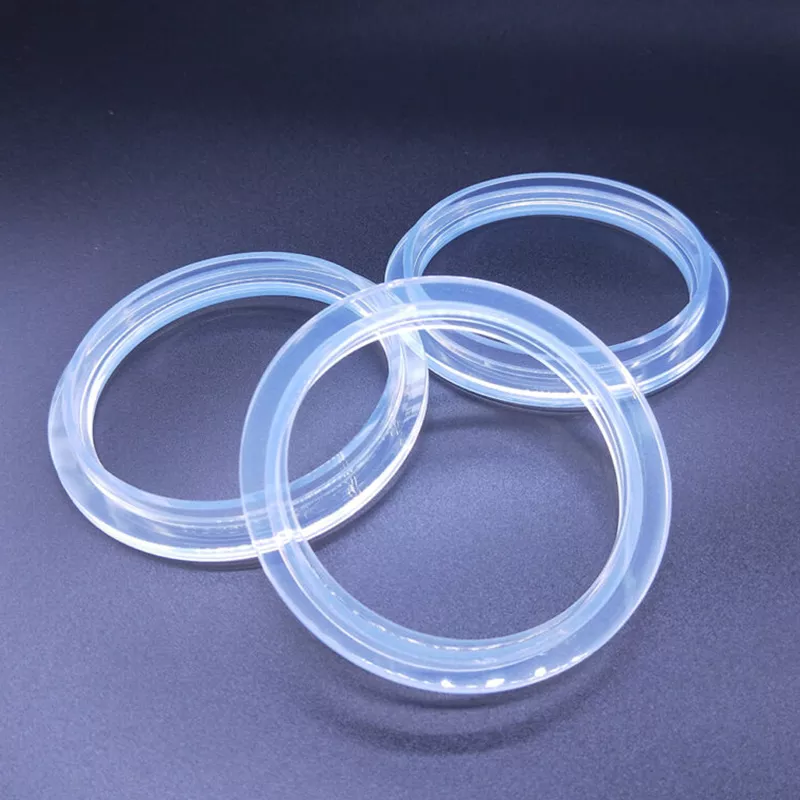

Liquid Silicone Rubber Injection Molding

Rapid-MFG has over 20 years’ experience in delivering cost-effective solutions for precision liquid silicone rubber (LSR) components and assemblies.

Liquid Silicone Rubber Molding

Rapid-MFG has many years of experience in liquid silicone rubber injection molding as a professional liquid injection molding company. Our manufacturing capabilities allow us to offer products and services ranging from rapid prototyping to high-volume production of precision parts.

We have chosen to use LSR exclusively through injection molding. Liquid silicone rubber is highly durable. With a high tear and tensile strength, excellent flexibility, insulating properties (even electrical conductivity), biocompatibility, and a hardness range of 5 to 80 Shore A, molded silicone rubber is stable over a temperature range of -75°F to 400°F. LSR is also resistant to water, oxidation, certain chemicals, and bacterial growth and will not corrode or contaminate other materials.

Concept-to-market silicone manufacturing

Rapid-MFG’s have full-service LSR manufacturing capabilities, including product development, prototyping with production representative tooling, advanced LSR mold-making, cleanroom silicone injection molding, multi-shot/multi-material molding, and secondary operations for single-source production.

Rapid-MFG can help you take advantage of LSR's design flexibility, and our advanced silicone molding technologies can cut your program costs and increase component quality.

Diversity in applications

LSR is used in many mission-critical applications where failure is not an option. Rapid-MFG specializes in molding tight-tolerance silicone components with exceptional shot-to-shot repeatability and zero-defect manufacturing.

Design flexibility

Silicone offers the ability to fill part geometries with tighter tolerances than are possible with a thermoplastic elastomer. Precise features, varying wall thickness, reduced likelihood of sink, small undercuts and negative draft are all possible with LSR.

Biocompatibility and performance properties

LSR is ideal for short- and long-term human implants because of its bacteria resistance, ease of sterilization, and odorless, tasteless and stainless characteristics.

Automatic silicone molding

The best way to decrease contamination is with automatic molding. Cycle times remain consistent, which is essential for liquid silicone molding, and it eliminates machine operators, reduces part variability, and lowers program costs, all while increasing quality.

Multi-material molding

Our specialty in molding multi-material components such as two-shot, insert, or overmolded parts can help expand your product’s performance options. Take advantage of Rapid-MFG’s global injection molding services.

Sustainable product life

Silicone is unaffected by environmental factors and remains attractive throughout the device’s life. It does not lose transparency with age or exposure to UV light, moisture, or heat, and is resistant to scratches, cracks, and breaks.

Our liquid silicone rubber molding process produces custom prototypes and end-use production parts in 15 days or less. We use aluminum molds that offer cost-efficient tooling and accelerated manufacturing cycles, and stock various grades and durometers of LSR materials.

Why Use Injection Molding?

Silicone injection molding offers clean, consistent results with tight tolerances that can be difficult to achieve with alternative methods such as compression or transfer molding.

A vital benefit of liquid silicone rubber over gum-based molding silicone substances is the cycle time. Depending on the stimulus and the cross-section of the part to be welded, the welding cycle time for liquid silicone parts ranges from 30 seconds to three minutes – our typical hardening time is from 25 to 50 seconds.

In contrast, gum base silicones might extract from 3 to 5 minutes of complete cycle time in a traditional silicone mold. Therefore, a solitary or two-tooth cavity injection mold will out-produce a multi-cavity mold. With fewer cavities required to sustain manufacturing, tooling prices and lead times are decreased in addition to component costs.

Alternatives

There are ways to create silicone-like parts without liquid silicone injection molding, by using an alternative process and/or material.

From a process perspective, the closest alternative is the injection molding of thermoplastic elastomers (TPE) or thermoplastic vulcanizates (TPV): these are pliable, impact-resistant plastics that are melted, injected, and solidified like other thermoplastics. An advantage of these materials is that they do not require metering and mixing. But although they have elastomeric properties, TPE and TPV are subject to theromoplastic weaknesses such as degradation in sunlight, and may not be suitable for certain medical applications.

Beyond injection molding, TPE is one of a handful of materials that can be made into a flexible 3D printing filament: a material used to additively manufacture rubberlike parts. TPU is another such material.

We Work With Nearly All Industries

Rapid-MFG’s Liquid Silicone Rubber Injection Molding service is perfect for addressing the various demands of different industries, including the automotive, medical, and consumer goods fields.

Ready To Start Your Next Project?

Our main objective is to present solutions to support the improvement of processes and the satisfaction of our clients’ expectations. Rapid-MFG’s team of Engineers will work with you to develop all the tools needed for industrialization and maximum process efficiency. The Quality Department will make sure that the final product fully matches your brief and technical specifications.

Explore Related Resources

Hello world!

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!