Quality Assurance

We deliver quality parts that meet requirements and exceed expectations.

Speed up Your Project Without Sacrificing Quality

Placing product quality at the forefront of our manufacturing process, we integrate quality control in every step to ensure superior prototypes and parts. We identify critical quality criteria in each project and use them as benchmarks to measure the performance of the final products.

Rigorous Quality Control Throughout Production

See how Rapid-MFG maintains the highest quality standards on our production process, from material selection to final inspection.

Well-Vetted Suppliers

We carefully select the suppliers that we work with, ensuring they have the materials we need available and are of top quality.

Quality Materials

Materials that arrive at our facility go through a series of tests, filtering top-grade materials from those with poor quality.

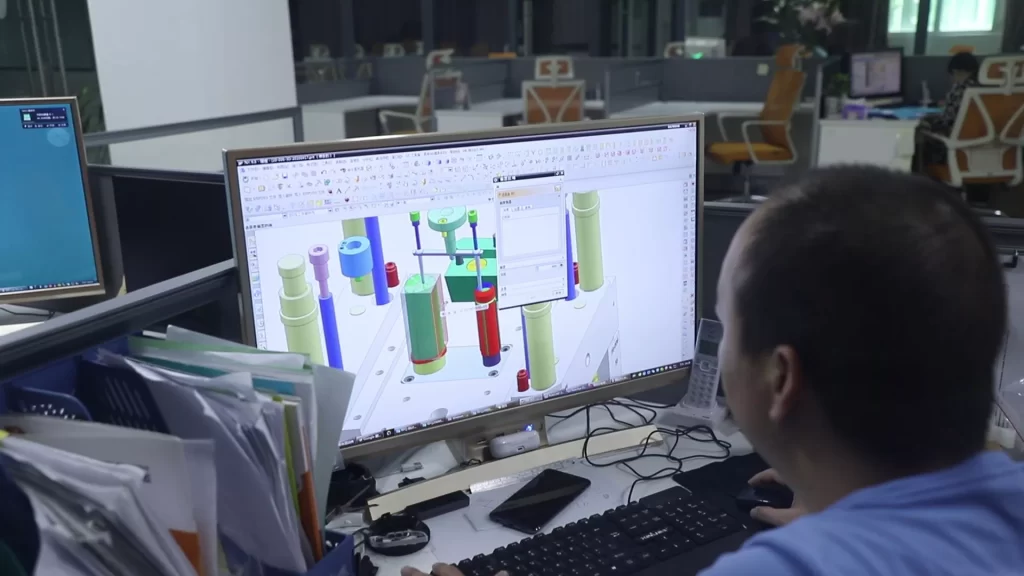

Professional Project Engineer

Expert designers review your project ideas and check how to apply the design best to make the prototype’s final mold.

Lean & Precise Manufacturing

We practice a lean manufacturing workflow that adheres to ISO-2768-m and ISO-2768-c standards for tight tolerances.

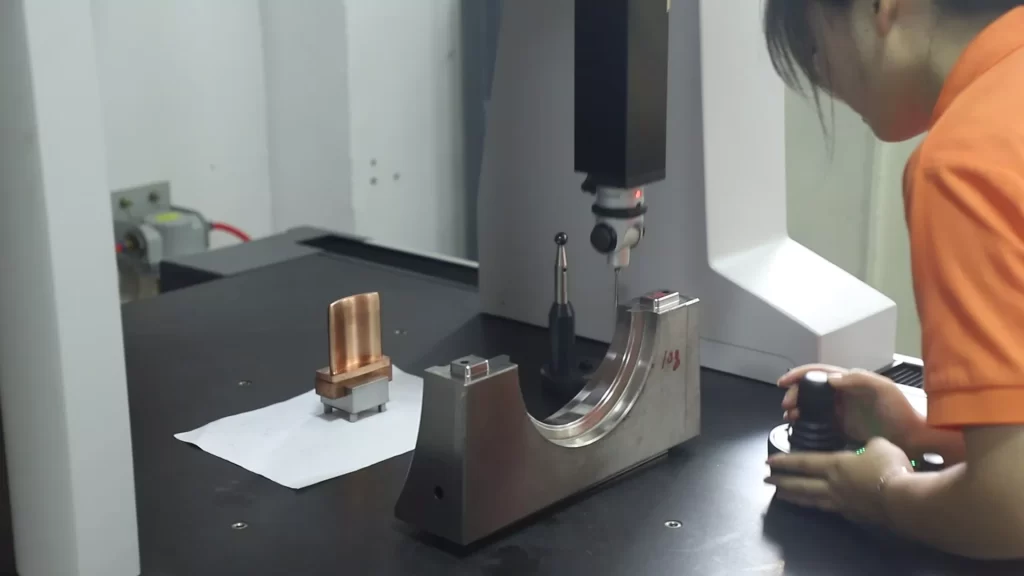

Rigorous Inspection

Our QC employees conduct a series of inspections, from material inspection, processing inspection, and finished product inspection.

Quality Control Process

Learn the most stringent inspection methods we applies over the course of the entire manufacturing process.

Technical assessment

Before the production stage begins, our engineering team performs a technical assessment on your parts design. This includes an assessment on important factors such as material, surface finish, structure, process, and other details of your 3D and 2D drawings.

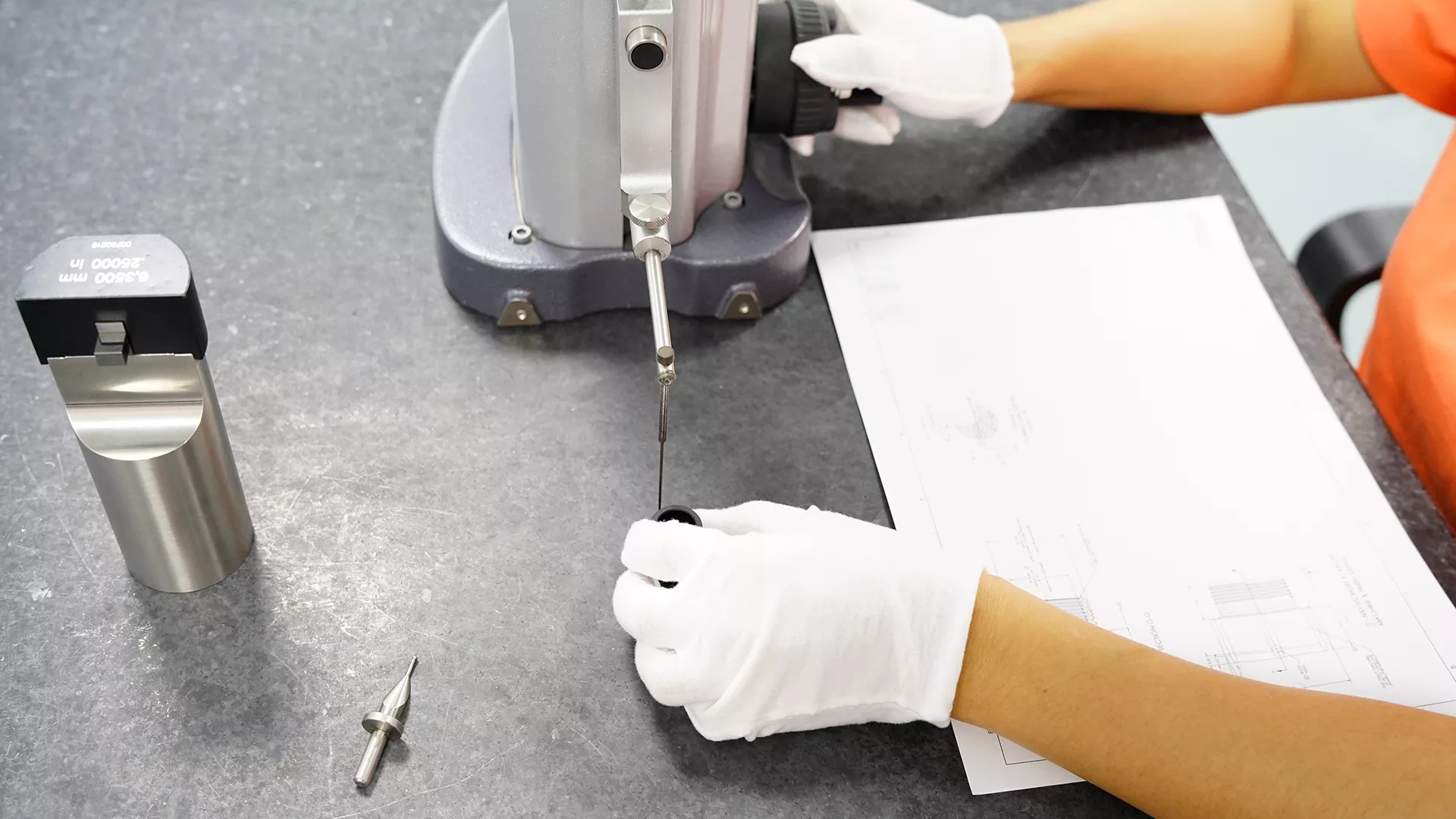

Material verification

On our customer’s request, we provide a certification of the material we used for making your parts. The report comes from the raw material manufacturer and usually includes: material heat number, material grade, material dimensions, mechanical properties, chemical analysis, etc.

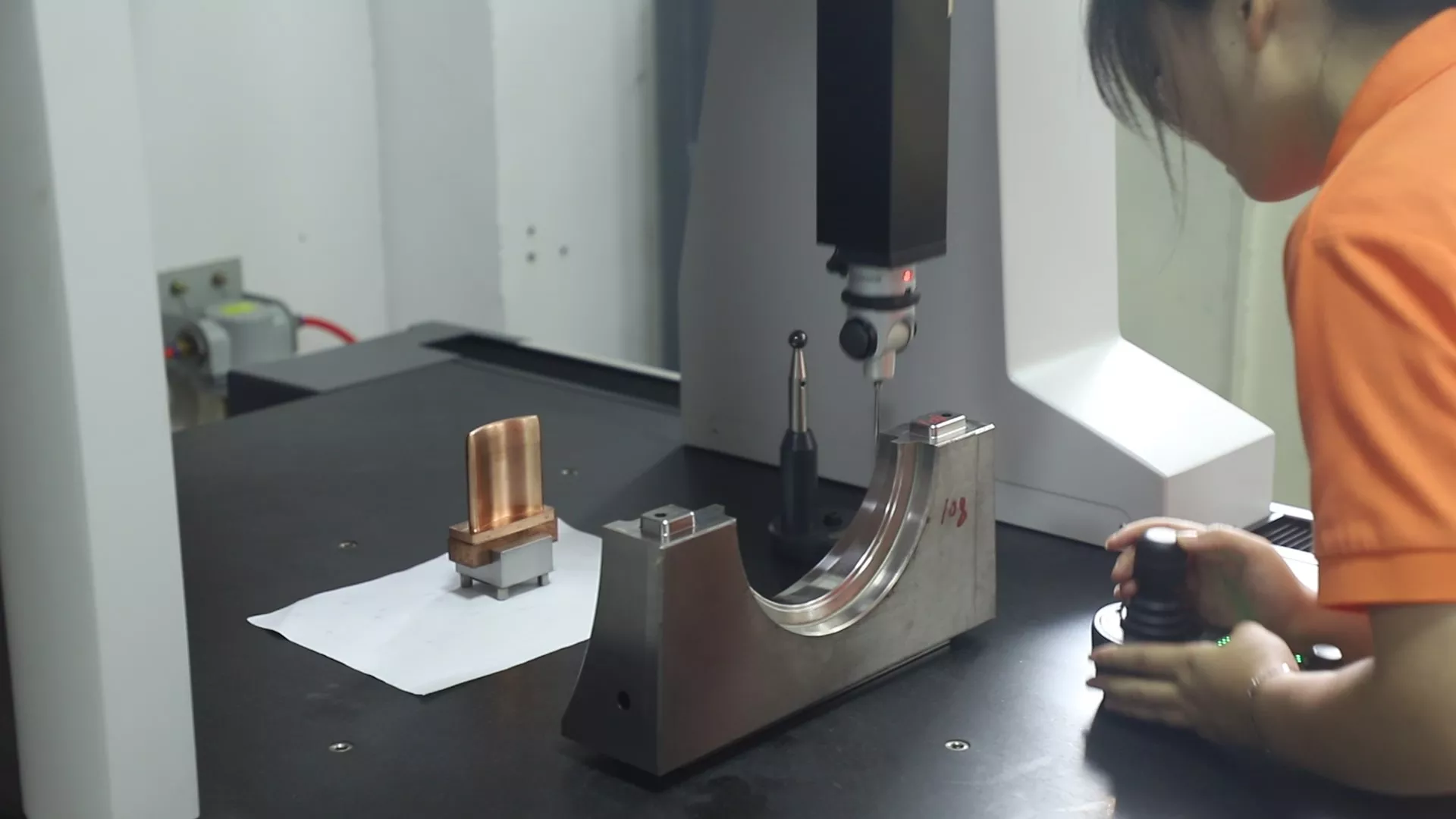

On-site inspection system

In precision machining, it is important that materials being worked on is always at the right position. With on-site inspection system, positions are examined automatically, and adjustments are made accordingly. Using on-site inspection system further helps avoids issues at the early stage, saving cost and time.

In-process quality control

At Rapid-MFG, we strictly obey the ISO9001:2015 requirements. The quality control staff conducts routine inspections for all parts that are being produced every 2 hours. This further prevents risks from happening.

Full-dimensional inspection report

For all orders, we provide full dimensional inspection report on request. This report will include the following: quantity of parts, critical dimensions, threads and tolerances, thicknesses and depths, part appearance, etc.

Packaging

Ensuring that the parts we manufacture are of the highest quality is important. We know about the unpredictability of logistics. Therefore, we make sure we lower the risk to the parts during our packaging process. Four layers of protection: 1. wrapping paper 2. EPE 3. foam 4. paper/wooden box are applied during the packaging process, ensuring that we deliver the most high-quality and beautiful parts to you.

State-of-the-art Facilities

To facilitate our strict quality control protocols, our production facility has dedicated workshops for meticulous inspection and state-of-the-art equipment.

Quality Reports on Your Request

Giving you added confidence to the prototypes and parts we manufacture for your brand, we can provide detailed quality reports showing material quality and product performance. These reports can come from either our in-house auditors or from third-party laboratories.

Quality Reports

For each order we receive, we can secure a list of quality reports per your request.

- Inspection report

- Full dimensional report

- Material test report

Certifications

As an established manufacturer of on-demand products, we have a library of certifications from reputable organizations.

- ISO 9001:2015

- ISO 13485:2016

- ROHS

- REACH