Rapid Tooling Services

Rapid-MFG provides superior rapid tooling services at highly competitive prices.

- One-stop Tooling Solutions

- Cost-effective and Fast Turnaround

- Free DFM for Excellent Results

Welcome to Rapid-MFG Rapid Tooling Solutions

Founded in 2002, Rapid-MFG is a custom rapid tooling facility in China; we offer a high-quality in-house production manufacturing shop for speedy turnaround times. Our tooling shop uses a paperless system to support your injection mold’s design, programming, and construction—a fully equipped mold manufacturing and repair shop.

Rapid-MFG is a genuinely ethical company with a reputation built on providing repeatable, reliable, and outstanding service to our customers, leveraging our team’s engineering knowledge and expertise to achieve significant added value savings for our customers.

We believe in providing our customers with technical excellence and becoming an extension of their production team. It is what makes our customers consistently choose us.

Our Rapid Tooling Processes

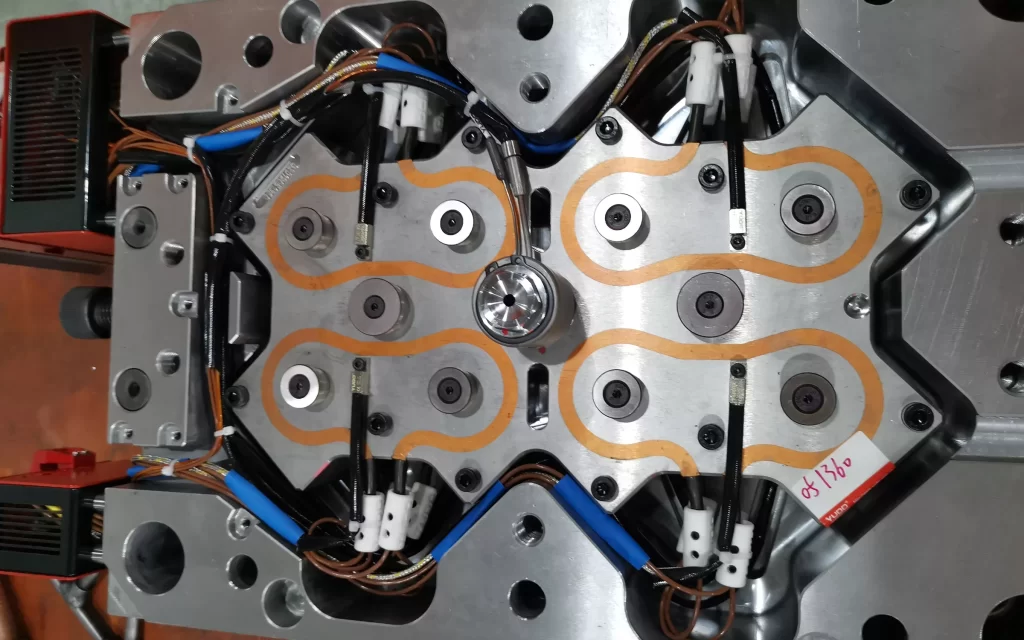

Fast Mold Tooling Making

Enjoy simplified mold design and quick mold making with soft steel or aluminum mold cavities for rapid results. Stock mold components and mold bases are also available for increased speed.

Low Volume Injection Molding

Asides from the regular production molds, we also combine injection molding with our rapid tooling capabilities, allowing us to produce low-volume injection molded parts quickly and cost-efficiently.

Advantages of rapid tooling

High Volume Manufacturing

More output as compared to other manufacturing processes.

Wide range of materials

Most thermoplastics and some thermosets and silicone can be injection moulded.

Process reduction

Complex assembly processes can be consolidated into one process.

Reproducibility

The mould can produce a large number of products without wearing out.

Materials for rapid tooling

Almost all plastics is ideal for prototype injection molding. The common used plastics are listed below:

- ABS

- ABS/PC

- Acetal

- Delrin

- HDPE

- LDPE

- Nylon

- PC

- PEEK

- PET

- PETG

- PMMA (Acrylic)

- Polycarbonate

- Polypropylene

- PPA

- PPE

- PS

- PSU

- Standard silicone

- Fluorosilicone (fuel and oil resistant)

- Medical-grade silicone

- Optical-grade silicone

Common Types Of Rapid Tooling

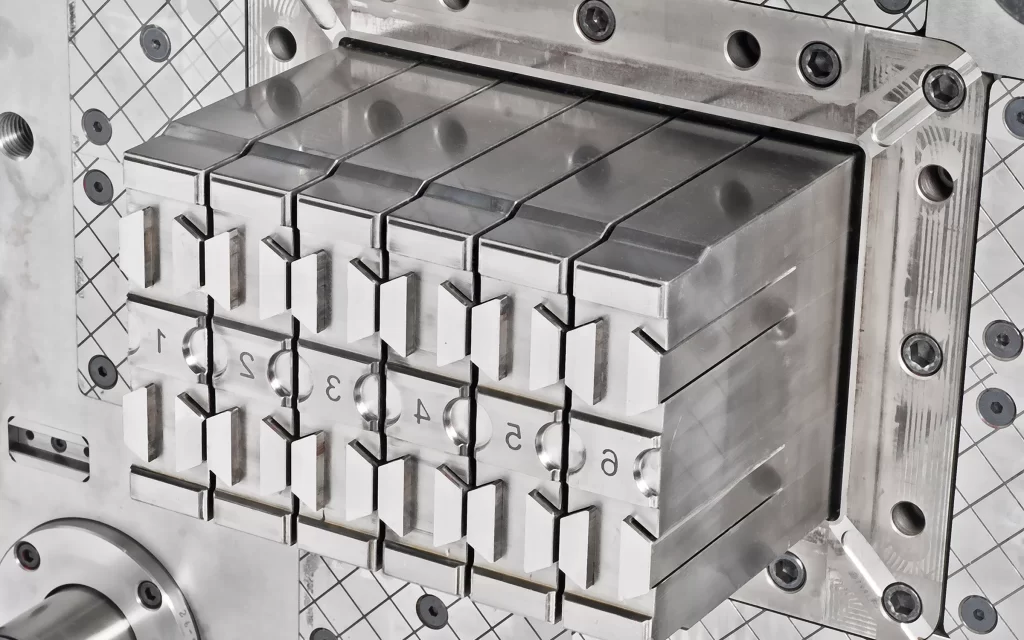

Aluminum Mold Tooling

This is the ideal choice for prototype injection molding because it is a cost-effective means of producing injection molded parts. Using aluminum ensures dimensional stability in the mold tooling, significantly reducing waste production and part deformation during production. Aluminum molds are also easier to cut, thereby reducing tooling costs by up to 25%. Using aluminum molds also reduces cycle times by 30-40%. All of these combine to ensure faster turnarounds.

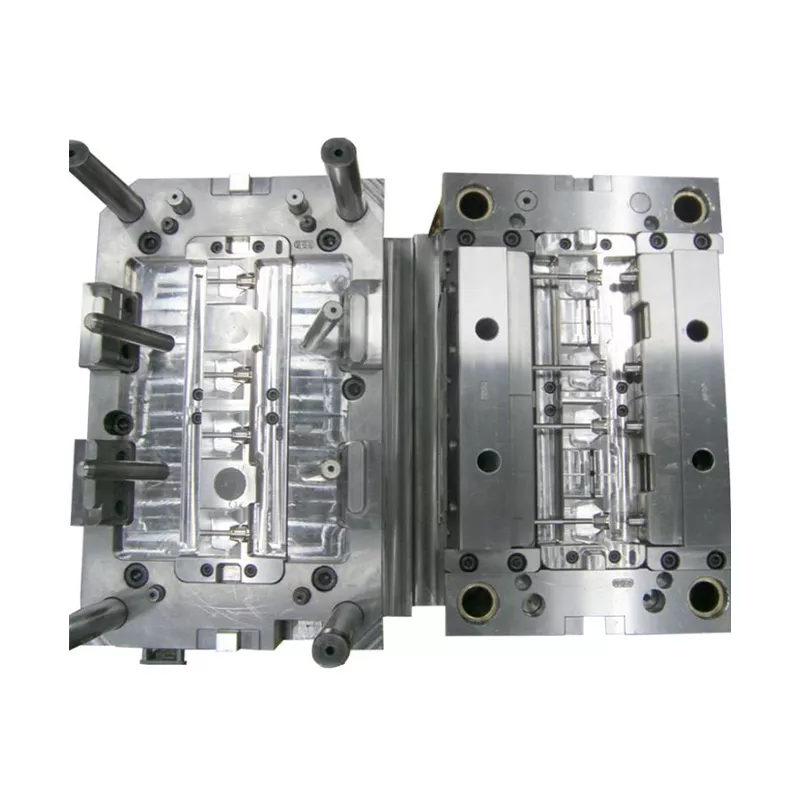

Steel Mold Tooling

Steel is a high-quality, solid, and sturdy material with a longer life cycle. It is more suitable for high-volume production runs and for producing molds from engineering-grade plastics. Despite its long life cycle, it is more expensive than aluminum and may require more time to produce mold tooling and prototypes.

Ready to start your molding project? Contact us today!

Rapid Tooling – Receive Plastic Parts In 3 Weeks Or Less

Production Mold

Our Rapid Tooling for Various Industrial Applications

Rapid-MFG has been the go-to source in the automotive, medical, food service, and other industries for affordable and reliable injection mold tooling services for over a decade.

Request Your Rapid Tooling Quote Today

After receiving your drawings, our engineers will analyze your custom parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.

Rapid Tooling news and industry updates

Advanced experience of German machine tools

Germany has long been recognized as a leading global producer of machine tools brought out by a combination of strong engineering

Large CNC Lathe Machining

Big bore CNC lathe is essential when manufacturing robust large parts and over size parts for a variety of applications which range from aerospace industry to equipment manufacturing.

Judging the accuracy of a CNC machining center

In the current environment in manufacturing, accuracy and precision in CNC machining centers are valuable commodities.