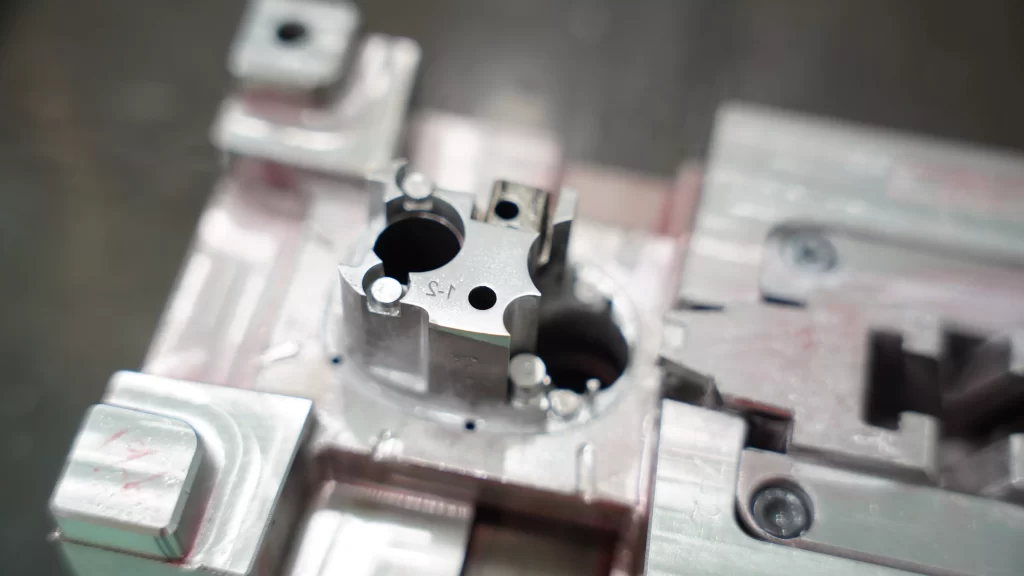

production tooling

Pressing business.In-house design and manufacture of specialized tools assures optimal production.

Custom production tools - plastic parts

Rapid-MFG manufactures prototypes, low volume, and production tools for various manufacturing applications. To support your most ambitious injection molding projects. Our meticulous process control and reliable material identification help ensure that millions of complex parts and assemblies are manufactured with consistent cycle times and the lowest possible cost per part. Our experienced and skilled CAD/CAM engineers and experts provide quality tooling solutions for today’s demanding manufacturing environments. We are independently certified to ISO 9001, 14001, 13485, and 45001 standards to ensure your complete peace of mind.

Contact us today to learn how our professional-grade, quality production tools can work for your company.

Reduce Mold Costs

Rapid-MFG has a variety of laminating tooling solutions ranging from low-temperature tooling cured at 180ºF to high-temperature aerospace tooling fixed at 375ºF to ultra-high temperature laminating tooling cured at 750ºF with cyanate and polyimide.

Traditional composite tools use complex egg crate structures. Tool surfaces are typically stripped from low-temperature, high-CTE foams and then post-cured independently, with stresses in the laminate causing movement.

With the technological development of Rapid-MFG, for the first time, low CTE foam can be used as a core material and retained in the tool through the use of increased inherent stiffness. In addition, Rapid-MFG eliminates the need for source tooling by processing the desired shape directly into blocks. By eliminating source tooling, the number of steps required to produce a finishing tool is reduced, thus reducing overall tooling costs.

A Chinese injection mold manufacturer with a difference

Proudly located in Shenzhen, China, Rapid-MFG is a Chinese manufacturer. We are proud of our injection mold tooling, known for tight tolerance Class A finished components for every market, from consumer products to government contracts.

What are production tools in manufacturing?

Production tooling refers to plastic injection molding tools and molds that can withstand the rigors of mass production while maintaining tight dimensional tolerances on each finished part.

To do this successfully, mold manufacturers must combine the highest quality raw materials, advanced software, precision mold design, and precision machining with building production molds that can be recycled millions of times without degradation. Only some manufacturers can provide this level of experience or attention to detail.

The Basis of Good Tooling Design

Tool design is probably the most critical factor affecting the quality of production molds and the quality of the parts they make. A good design allows the cavity to be filled quickly while maintaining stable and repeatable dimensional tolerances for all part features.

Achieving this stability over long production runs requires careful design and manufacturing of the mold’s cooling channels. This helps the mold tool withstand the thermal stresses of thousands or even millions of heating and cooling cycles.

Production Tooling Materials

There are many types of hardened and semi-hardened tool steels to choose from, including P20, NAK80, H13, and S136. They differ in the degree of corrosion resistance, toughness, thermal efficiency, and the ability to take a high polish.

That’s why the choice of tool material that’s best suited for your project depends on your intended production volume, the surface finish of the part, the type of resin that’s being injected, and the complexity of the tool design.

As with all tooling design decisions, we advise consulting with your manufacturing partner in advance to clearly understand your options.

Quality and customer service mean everything to us

At Rapid-MFG, you know your project is being built and managed by people who have worked in the industry for decades. We understand the urgency and perfection of our customer’s requirements, and they continue to choose Rapid-MFG for their injection molding services. Time and time again, we deliver high-quality, cost-friendly tooling for producing the same part, whether the first or the millionth.

production tooling news and industry updates

Advanced experience of German machine tools

Germany has long been recognized as a leading global producer of machine tools brought out by a combination of strong engineering

Large CNC Lathe Machining

Big bore CNC lathe is essential when manufacturing robust large parts and over size parts for a variety of applications which range from aerospace industry to equipment manufacturing.

Judging the accuracy of a CNC machining center

In the current environment in manufacturing, accuracy and precision in CNC machining centers are valuable commodities.