Precision mold making service -Rapid-MFG

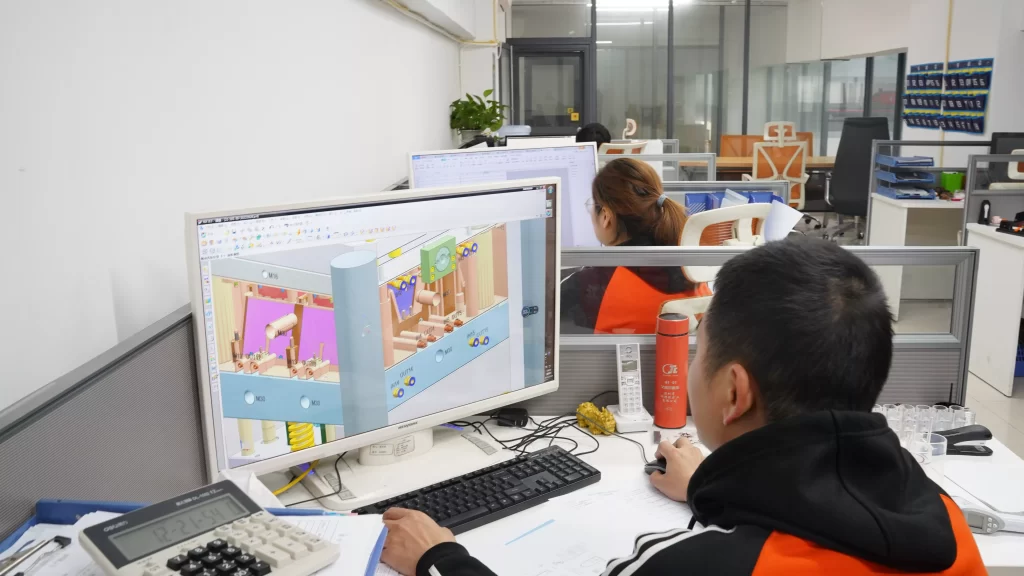

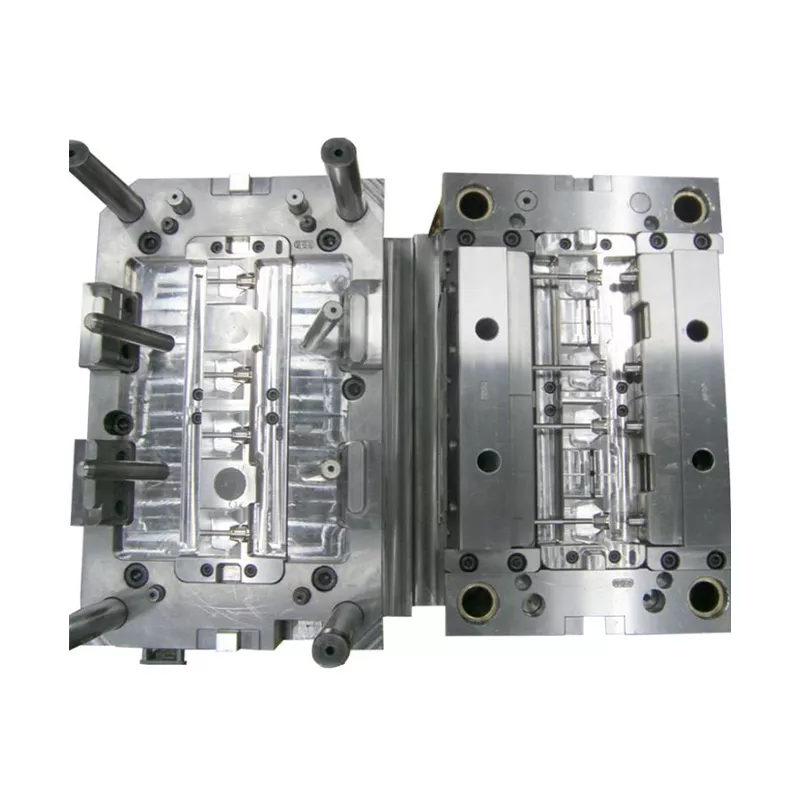

Need mold making supplies for mass-production parts? With our in-house mold making facilities and the resources of our partners, we can provide injection molds for hard plastics and rubber, metal injection molds for all types of precision stainless steel parts, and die-casting molds for aluminum, magnesium, and zinc. We offer cost effective, high quality molds to meet all your project needs. In addition, we provide long-term mold service maintenance and improvements for new product requirements. Using our CNC machinery, EDM technology, and the skills of our experienced mold makers to meet your mold build and specified surface finish requirements ultimately, such as Mold-Tech texturing or high polish SPI grade mold finishes. Rapid-MFG will provide the mold that meets your needs to assist in quality injection molded parts. Our in-house engineering department is available to assist with part design work.

Rapid-MFG can handle it without a hitch, whether you need a prototype mold for small production runs or a mass production mold for millions of runs.

Full Service Mold Making Department

- Comprehensive mold management

- Full Service Mold Maintenance

- Quick mold enhancements completed in house

- Build fixtures and gages for consistent quality parts

- Mold capabilities include CNC 3D Machining, EDM, polishing and texturing.

- Hard and soft tooling

- Tool history documentation

- Various frames and configurable molds

- Correct issues with gating, venting and cooling

- Complete refurbishments

- Inspection fixtures are engineered and built in house

Mold making sources

- Mold Design

- 3D Prototypes and rapid prototypes

- In house mold fabrication

- Quick turn tooling to get your product to market quickly

- Off shore alliances for high quality for low-cost

- A factory established for more than 20 years

- Wide mold material selection includes Aluminum, Stainless Steel and Tool Steel

- Preventative maintenance schedule to stay ahead of unnecessary mold damage and mold wear

- Decisions of number of cavities to make the most of the mold.

Mold Making Processes

Mold making is a complex process that requires a high level of skill and experience. Although each case is different, a typical order for a set of molds may go something like this:

1. DFM

As soon as the customer confirms the order of molds, we will start to do an initial analysis of the parts to get an idea of the part line, gate positions, etc.

2. Mold design and mold flow analysis

The second step involves the use of predictive modeling software which allows us to see how the molten material will behave when it enters the mold, allowing for further improvements to the design.

3. CNC machining and EDM

We make the first molds using high-quality machining equipment, with the plastic, steel, aluminum, etc. chosen by the customer.

4. T1 sample

With the newly made molds, we make a T1 sample to have a clear vision of how the customer’s final molded parts will turn out.

5. Improvement if necessary

Based on our analysis of the T1 sample, we review the mold design and make any adjustments needed.

6. Commence production and shipping

We manufacture the molds in accordance with the final specifications before shipping them to the customer.

Molding projects completed by Rapid-MFG

We help many industries to make precision molds

Ready To Start Your Next Project?

Whether you need a rapid mold prototype or a finished production run, Rapid-MFG has the skills and experience to guarantee superior results. We offer specialty tooling, custom casts, and full production runs for all manner of rubber, metal, and plastic products, and we strive to meet the needs of clients across industries. To learn more about whether our capabilities are right for you, contact our team, or request a quote to get started.

mold Making news and industry updates

Advanced experience of German machine tools

Germany has long been recognized as a leading global producer of machine tools brought out by a combination of strong engineering

Large CNC Lathe Machining

Big bore CNC lathe is essential when manufacturing robust large parts and over size parts for a variety of applications which range from aerospace industry to equipment manufacturing.

Judging the accuracy of a CNC machining center

In the current environment in manufacturing, accuracy and precision in CNC machining centers are valuable commodities.