CNC machining services

Rapid batch customization of high-precision metal and plastic parts.

On-demand manufacturing

We create and ship parts for customers across the US and the world

Networked, global infrastructure

Remove the logistical risk typically associated with outsourced manufacturing

Imagine, design, build

Access industry-grade materials and expert engineering insight

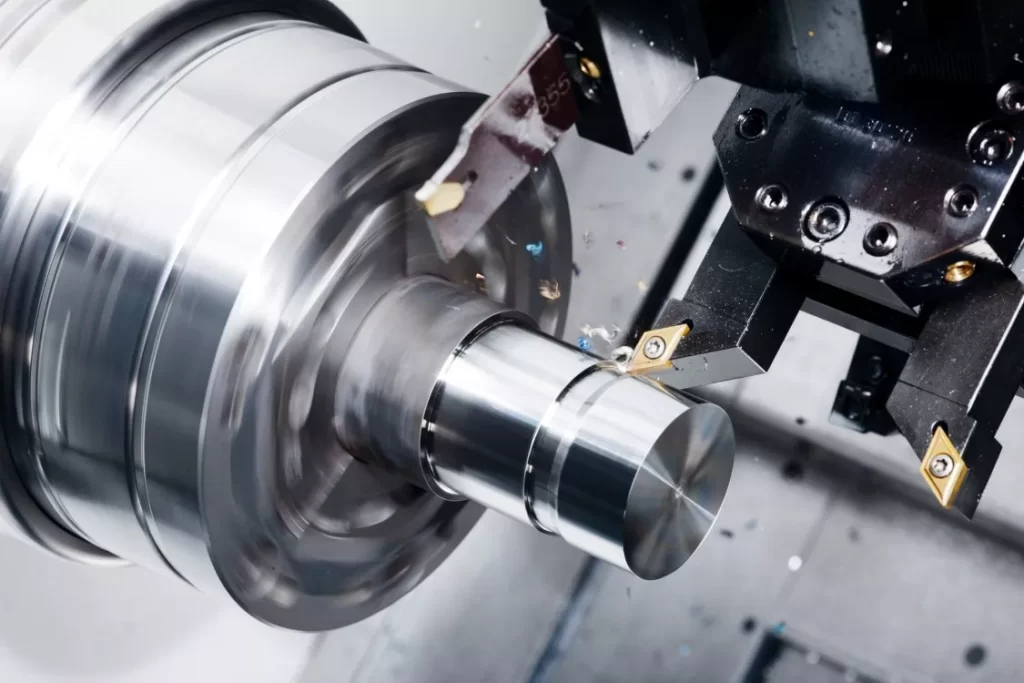

Our CNC capabilities include milling and turning services, enabling complex geometries and angles to be achieved with cost-effective speed and accuracy, and can quickly scale from prototypes and single parts to high-volume production requirements.

Start your CNC machining project today. Upload your CAD files to our instant quoting system to receive a quote, work with our engineers to optimize your design, and go into production when it’s ready. You can specify the post-production and finishing options required for the part, as well as any inspection requirements. When your order is ready, we will package the finished parts and ship them to you.

Explore our CNC machining services

Our CNC machining capabilities meet a wide variety of manufacturing needs. Explore our milling and turning services:

CNC Milling

CNC mills are effective for geometric designs and rapid production requirements. Our CNC capabilities include both 3-axis and 5-axis mills.

CNC Turning

CNC turning is a process in which an automated lathe shapes a rotating workpiece. Turning is useful for shaping rounded or cylindrical geometries.

CNC machining applications

Precise and quick to produce, CNC machined parts serve a spectrum of industrial applications:

Tooling

Manufacture parts with complicated cuts and angles using a variety of precision cutting, drilling, and lathing tools.

Niche manufacturing

Cut durable metal and plastic products that alternative processes can’t create. The CNC turning process is ideal for creating cylindrical parts.

Medium-to-high-volume production

Perform cost-effective production runs in the hundreds and thousands, scaling up and down as your business needs change.

Metal fabrication

Meet demand for high quality metal parts with exceptional tight tolerance requirements.

CNC machining materials

Manufacture CNC machined parts in a selection of industrial metals and plastics:

| Plastic | Aluminum | Stainless Steel | Other Steel | Other Metal |

|---|---|---|---|---|

| ABS | 2024 | 303 | Mid steel | Brass |

| Nylon 6 | 6061 | 304 | Alloy steel | Copper |

| Acetal (Delrin) | 6082 | 316 | Tool steel | Titanium |

| Polycarbonate | 7050 | 17-4 | Contact us for additional metal machining options | |

| PVC | 7075 | 420 | ||

| HDPE | ||||

| PTFE (Teflon) | ||||

| PEEK | ||||

| Nylon 30%GF | ||||

| UHMW |

Surface Finishes for CNC Machining

CNC machining leaves visible tool marks during the process of removing portions of the block’s surface to create desired shapes. If don’t want as-machined parts, select a surface finishing for your custom parts. At Rapid-MFG, we offer several common surface finishes that help improve functionality and aesthetics.

| Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. | Learn More>> | |

Bead Blasting | Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments. | ABS, Aluminum, Brass, Stainless Steel, Steel | n/a | Matte | Learn More>> | |

| Powder Coating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss | Learn More>> | |

| Electroplating | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. | Aluminum, steel, stainless steel | n/a | Smooth, glossy finish | Learn More>> | |

| Polishing | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection. | Aluminum, Brass, Stainless Steel, Steel | n/a | Glossy | Learn More>> | |

Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | n/a | satin | Learn More>> |

CNC Machining Tolerances and Standards

With precision CNC machining services, Rapid-MFG is your ideal partner to create precision machined prototypes and parts. Our standard CNC machining tolerances for metals is ISO 2768-f and for plastics is ISO 2768-m. We can also achieve special tolerances as long as you indicate your requirements on your drawing.

| Standards | CNC Milling | CNC Turning |

| Maximum Part Size | 4000×1500×600 mm 157.5×59.1×23.6 in. | 200×500 mm 7.9×19.7 in. |

| Minimum Part Size | 4×4 mm 0.1×0.1 in. | 2×2 mm 0.079×0.079 in. |

| Minimum Feature Size | Φ 0.50 mm Φ 0.00197 in. | Φ 0.50 mm Φ 0.00197 in. |

| Standard Tolerances | Metals: ISO 2768-f Plastics: ISO 2768-m | Metals: ISO 2768-f Plastics: ISO 2768-m |

| Linear Dimension | +/- 0.025 mm +/- 0.001 in. | +/- 0.025 mm +/- 0.001 in. |

| Hole Diameters (Not Reamed) | +/- 0.025 mm +/- 0.001 in. | +/- 0.025 mm +/- 0.001 in. |

| Shaft Diameters | +/- 0.025 mm +/- 0.001 in. | +/- 0.025 mm +/- 0.001 in. |

| Edge Condition | Sharp corner will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing. | |

| Threads and Tapped Holes | Diameter: Φ 1.5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter | Diameter: Φ 1.5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter |

| Rapid-MFG can produce threads of any specification and size required by our customers. | ||

| Text | Minimum width of 0.5 mm, depth of 0.1 mm Rapid-MFG can use CNC engraving or laser carving to create standard text based on customers’ requirements. | Rapid-MFG can use laser marking to create standard text for CNC turned parts. |

| Lead Time | 5 business days | 5 business days |

CNC machining case studies

Rapid-MFG CNC machining services solve manufacturing challenges every day. Explore our CNC machining projects to learn more about the ways that our work creates an impact.

Why Choose Our Custom CNC Machining Service

Online Instant Quote & DFM Analysis

No need to write a quote request email, get instant CNC quotes by simply uploading your design files. Our digital quoting platform analyzes your part geometry, and provides real-time & competitive pricing and comprehensive DFM feedback.

Consistent High Quality

We strictly implement a quality management system to ensure consistent, expected quality on the products. Full inspections also make sure you receive precision machined parts devoid of unwanted defects.

Fast Lead Time

Not only do we have a digital CNC machining services platform that provides faster ordering process, we also own domestic workshops and state-of-the-art machinery to accelerate the production of your prototypes or parts.

24/7 Engineering Support

No matter where you are, you can get our 24/7 engeering support all year around. Our experienced engineer can provide you with the most appropriate solution to your part design, material selection, and surface finishing options and even lead time.

Trusted by engineers across the globe

Rapid-MFG allows our company to seamlessly expand to new models and segments as the market for EV motorcycles grows. With Rapid-MFG, turning around new designs and prototypes is faster and less expensive than with any other manufacturer. We’re able to outmaneuver large companies and plan for our future without worrying about scaling. We can’t thank Rapid-MFG enough for their partnership. The quality of the work they’ve done for us is unbelievable.

John Doe

Codetic

Rapid-MFG allows our company to seamlessly expand to new models and segments as the market for EV motorcycles grows. With Rapid-MFG, turning around new designs and prototypes is faster and less expensive than with any other manufacturer. We’re able to outmaneuver large companies and plan for our future without worrying about scaling. We can’t thank Rapid-MFG enough for their partnership. The quality of the work they’ve done for us is unbelievable.

John Doe

Codetic

Get a quote for your CNC machined parts

Quoting is simple with Rapid-MFG. Learn more about our quoting process.

CNC machining news and industry updates

Find industry news, resources, insight into the CNC machining process, and more, on the Rapid-MFG blog.

Advanced experience of German machine tools

Germany has long been recognized as a leading global producer of machine tools brought out by a combination of strong engineering

Large CNC Lathe Machining

Big bore CNC lathe is essential when manufacturing robust large parts and over size parts for a variety of applications which range from aerospace industry to equipment manufacturing.

Judging the accuracy of a CNC machining center

In the current environment in manufacturing, accuracy and precision in CNC machining centers are valuable commodities.