Overmolding service

- Enhanced consistency

- Strong parts

- Durable components

- As fast as 1 day delivery

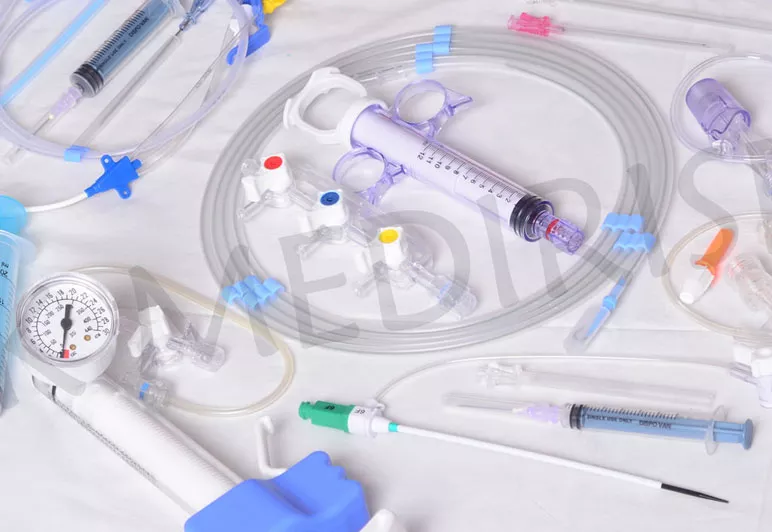

Medical/Pharmaceutical

We can add ergonomic features to medical instruments or devices. As well as aesthetic and identifying features on products.

Military/Defense

Overmolding can be used for grips and protective touchpoints on dials, instruments, and more needed in the field.

Industrial/OEM

Overmolding can add protective features and vibration resistance for products. To make them more durable for certain applications.

Injection Overmolding Services - Rapid-MFG

Rapid-MFG offers in-house overmolding services, offering the widest selection and high-quality overmolding services for all your injection molded part manufacturing needs; plastic injection overmolding requires molding new around or covering existing plastic molded forms form. The process allows different materials and shapes to be closely molded without a separate assembly process. This plastic injection molding process is very useful for making complex parts and has some unique properties that may suit your project. Overmolding is a very established injection molding process on the market. Our professionals will advise you based on our 22 years of experience in injection molding to make your products competitive in the market.

Our Capabilities

- Designing for manufacturability

- Creating out-of-the-box solutions to meet our customers’ specific needs

- Providing creative solutions to solve our customers’ most challenging injection molding dilemmas in the medical, electronics, defense, aerospace, and automotive industries

- Providing fast turnaround times and quick response to customer requests

- Maintaining strict material management and quality assurance processes

- Maintaining a companywide focus on quality

- Maintaining a safe working environment

Design considerations

Unlock the potential of your overmolding project with the following injection molding design considerations, including tooling details, available materials and colors, and finishing and post-processing options.

| Substrate wall thickness | The thickness of the substrate’s wall determines how effectively the overmold material flows in, on, and around the substrate. Due to temperature differences between substrate and overmold materials, having an inconsistent wall thickness can lead to warping, increase flash, and render fills incomplete. Ensure that the wall thickness of the substrate and thickness of the overmold are even and consistent from the beginning of the process. Wall thicknesses ranging from 0.060″ to 0.120” (1.5 mm-3 mm) will ensure good bonding in most overmolding applications. |

| Maximum part size | 800 x 800 x 400 mm 31.5 x 31.5 x 15.7 in |

| Minimum part size | 1 x 1 x 1 mm 0.04 x 0.04 x 0.04 in |

| Tolerance | Best achievable tolerance: ±0.001″ (0.025mm) Standard: ±0.005″ (0.127mm) For larger part tolerances please contact a Fast Radius engineer |

| Lead time | As low as 2 weeks for T1 samples After T1 sample approval, lead time for < 10,000 parts is as low as 1 week |

| Tool validation | Standard process is to produce a small set of T1 samples for approval before initiating full production |

| Maximum press size | 1600T |

| Minimum order size | 100 parts and $5000 |

| Set-up fee | $500 per mold per order (applies to sample runs after initial T1 samples or engineering changes) |

| Rapid tooling | Molds with steel cavity and core with a shot life of 5,000-10,000 shots Typically machined in 2 weeks |

| Production tooling | Steel tool with shot life up to 1M shots Ability to integrate side-pulls or cam-actions Typically machined in 3 weeks |

| Multi-cavity or family molds | Multiple identical cavities or family of parts machined into a single tool Allows for more parts to be produced per shot, minimizing unit costs |

| Overmolds | Premade parts are placed into the mold and molded over Allows for multi-material injection molding |

Materials Used For Overmolding

We offer a wide range of materials for overmolding projects, depending upon the geometry, complexity, and requirements of your project. These materials can be divided into three different categories, including:

Rigid Plastics

ABS

Polypropylene

Polycarbonate

Acrylic

Nylon

POM

PTFE

PBT/PBT-PC

PEEK

HDPE

PVC

PPS

PI

PAI

UPE/UHMW

PVDF

ULTEM (PEI)

Overmolding finishing, post-processing

We offer multiple finishing options to complete the products made with the overmolding process. You can choose from any of the following depending upon your application’s requirements:

Standard Finish

Interior, non-cosmetic finish according to the geometry of the mold.

SPI Finishes

Range of SPI finishes from Grade 3 diamond / high polish to 320 stone low polish. These Finishing options include SPI A-1, SPI A-2, SPI A-3, SPI B-1, SPI B-2, SPI B-3, SPI C-1, SPI C-2, SPI C-3, SPI D-1, SPI D-2, and SPI D-3.

Threaded Inserts

We can install the most commonly used and popular standard inserts in UNF and metric sizes.

As Molded

As the name suggests, the mold will remain ‘as it is’ – without any secondary texturing or polishing.

Mold Texturing

Creating textures on the molds so that it shows on the final product. This finishing option includes matte, swirls, patterns, and lines.

Laser Engraving

Engrave part numbers, designs, logos, or any other specified printing onto your parts.

Pad Printing

Application of an ink-based design to the surface.

Painting

Painting the surface with standard colors or Pantone matching, including Primer and topcoat. Masking available; EMI (copper) paint.

Get an instant quote for your overmolding project

Backed by decades of expertise in design, development, manufacturing and supply of progressive metal stamping tools and components.

Our Overmolding Service for Various Industries

Rapid-MFG works with leading manufacturers from different industries to support growing demands and streamline their supply chain. The digitalization of our custom injection molding services helps more and more manufacturers bring their idea to products.

Request Your Free OverMolding Quote Today

After receiving your drawings, our engineers will analyze your custom OverMolding parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.

Explore overmolding news and industry updates

Advanced experience of German machine tools

Germany has long been recognized as a leading global producer of machine tools brought out by a combination of strong engineering

Large CNC Lathe Machining

Big bore CNC lathe is essential when manufacturing robust large parts and over size parts for a variety of applications which range from aerospace industry to equipment manufacturing.

Judging the accuracy of a CNC machining center

In the current environment in manufacturing, accuracy and precision in CNC machining centers are valuable commodities.