Our Capabilities

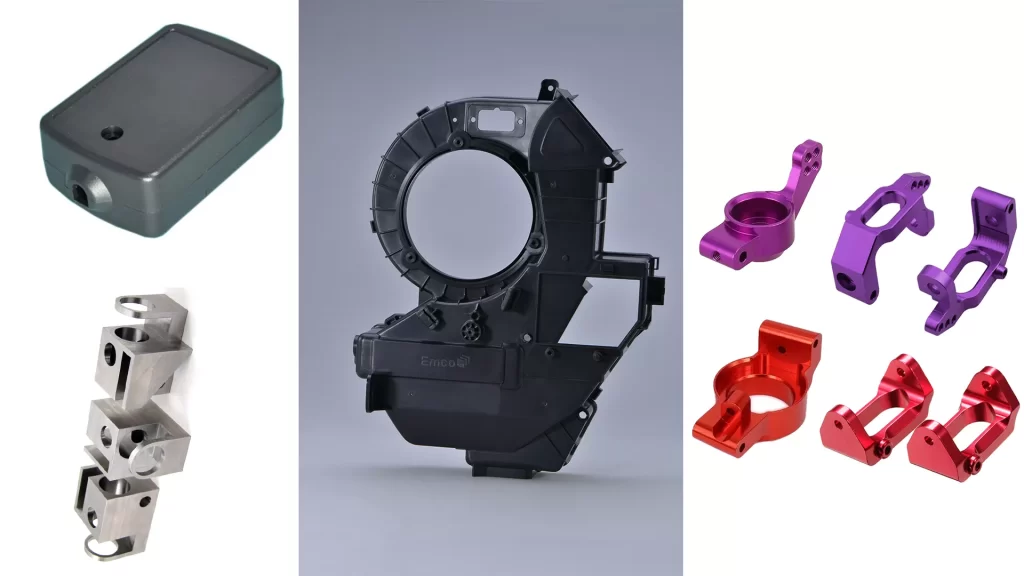

Our extensive manufacturing capabilities are designed to meet your custom prototyping and production needs. We specialize in CNC machining, injection molding, sheet metal fabrication, 3D printing, and other advanced technologies to meet most industries’ prototype or part production needs.

Meet your prototype and part manufacturing requirements

Leading the industry in rapid prototyping and parts manufacturing, we open the door for product designers and engineers to develop unique products for their market. Our robust production capabilities, comprehensive services, and strong quality control offer fast and cost-effective solutions that will help you improve your brand.

The support Rapid-MFG can provide

Our expert engineers review the drawings you send with over 20 years of combined experience designing high-performance, cost-effective, and easy-to-manufacture molds. Several factors are considered in each design file to ensure we make the best molds possible.

- Wall Thickness

- Shrinkage

- Stress

- Functionality

- Aesthetics

- Dimensional Stability

- Cost

Processing Services We Support

To help designers and engineers bring their concepts into reality, we offer a variety of services that include rapid prototyping and mass production options.

Rapid-MFG, provides high tolerance CNC machining processes including 3, 4, 5 axis CNC milling, CNC turning, and post-processing services for your diverse manufacturing requirements.

| Type | Tolerance |

| Linear dimension | +/- 0.025 mm

+/- 0.001 inch |

| Hole diameters(not reamed) | +/- 0.025 mm+/- 0.001 inch |

| Shaft diameters | +/- 0.025 mm+/- 0.001 inch |

| Smallest thread size available | M1x0,25 |

| Part size limit | 950 * 550 * 480 mm37.0 * 21.5 * 18.5 inch |

At Rapid-MFG, we offer various injection molding services which includes rapid tooling, family molds, multi-cavity molds, over molding, etc., for your manufacturing needs. Each service is based on various manufacturing standards highlighted below:

| Part size (mm) | Production tooling | Rapid tooling |

| 1~22 | ±0.06~0.09 | ±0.08~0.13 |

| 22~70 | ±0.11~0.17 | ±0.14~0.24 |

| 70~160 | ±0.20~0.29 | ±0.30~0.43 |

| 160~250 | ±0.36~0.44 | ±0.51~0.68 |

| 250~315 | ±0.44~0.55 | ±0.68~0.85 |

| 315~500 | ±0.70~0.90 | ±1.08~1.38 |

| 500~1000 | ±1.20~1.90 | ±1.83~2.90 |

| 1000~1400 | ±2.30~2.65 | ±3.50~4.05 |

| 1400~2000 | ±3.05~3.80 | ±4.65~5.80 |

We have experience and the right sheet metal fabrication services necessary to bring that YOUR idea to life. This includes services like high tolerance and wide thickness range laser cutting, bending capabilities, and other post-processing options.

| Dimension detail | Tolerance |

| Edge to edge, single surface | +/- 0.005 inch |

| Edge to hole, single surface | +/- 0.005 inch |

| Hole to hole, single surface | +/- 0.005 inch |

| Bend to edge / hole, single surface | +/- 0.010 inch |

| Edge to feature, multiple surface | +/- 0.030 inch |

| Over formed part, multiple surface | +/- 0.030 inch |

| Bend angle | +/- 1° |

3D Printing is the best service if you want the best functional parts prototyping. At Rapid-MFG, we provide you with the best technologies in 3D printing such as FDM, SLA, SLS, Polyjet. For other technologies associated kindly contact us.

| Process | Min. wall thickness | Layer height | Max. build size | Tolerance | |

| SLA | 1.0 mm | 50 – 100 μm | 250 * 250 * 250 mm | ± 0.5% with a lower limit of ± 0.5 mm (± 0.020″) | |

| SLS | 1.0 mm | 100 μm | 420 * 500 * 420 mm | ± 0.5% with a lower limit of ± 0.15 mm (± 0.006″) | |

| FDM | 1.0 mm | 100 – 300 μm | 500 * 500 * 500 mm |

|

Urethane casting (also known as RTV molding, cast urethane, and silicone molding) is a fabrication method that uses silicone molds to produce production-grade elastomeric parts with 10-200 units.

| Typical lead time | Up to 20 parts in 15 days or less, depends on the part specification and volumes. |

| Accurate | ± 0.3% (with lower limit on ± 0.3 mm on dimensions smaller than 100 mm) |

| Minimum wall thickness | To ensure that the mold is filled properly, a wall thickness of at least 0.75 mm is necessary. For best results, we recommend a wall thickness of at least 1.5 mm |

| Maximum part dimensions | The size of the mold is limited by the dimensions of the vacuum chamber (1900 x 900 x 750 mm) and by the volume of the product (maximum volume: 10 liters) |

| Typical quantities | Up to 25 copies per mold (depending on the mold’s complexity and the casting materials) |

| Color & Finishing | Pigment is added to the liquid polyurethane prior to casting, custom painting and texture. |

CNC machining, 3d printing, sheet metal fabrication, and more are available to support rapid prototyping. We offer a full range of surface finishes and materials to support one-roof and rapid manufacturing and processing to help test your design.

Custom Manufacturing On Demand

Along with our strong manufacturing capabilities, we also provide you the ability to choose the manufacturing volume and other processes that match your production needs.

Rapid Prototyping

We use the latest technology and equipment to produce prototypes quickly and accurately, helping clients to reduce their product development time and costs.

Capability: 20-500

Lead Time: 10 business days

Low Volume Manufacturing

For batch manufacturing, we have several options to accommodate your requirements, like vacuum casting, CNC machining, and plastic injection molding.

Capacity: 500-1000

Lead Time: 15 business days

High Volume Manufacturing

To complete large-volume manufacturing requirements, take advantage of our plastic injection molding, sheet metal fabrication, and other production processes.

Capacity: 1000+

Lead Time: 20 business days

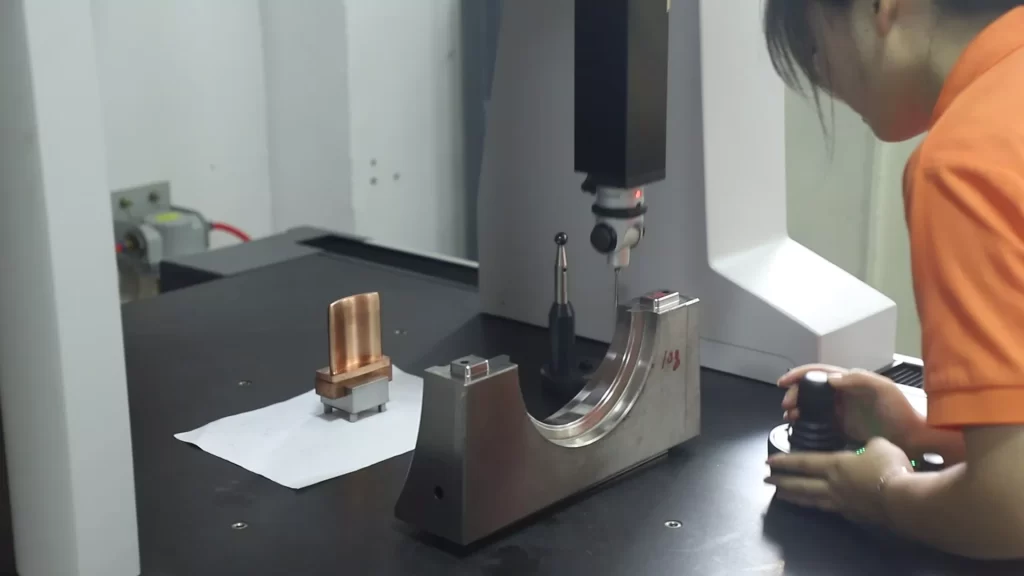

Quality Control Can be Witnessed Everywhere

Rapid-MFG takes pride in our strict quality control standards applied throughout each section of our production process. Our expert quality auditors pay close attention to detail, inspecting each product for inconsistencies.

IS09001:2015 Certified Factory

Our factory holds an ISO 9001:2015 certificate – a testament to our dedication to quality.

Well-vetted Suppliers

Close partnerships with thousands of reliable material suppliers guarantee constant access to quality materials.

Rigorous Quality System

Our strict commitment to quality control regulations ensures consistent quality is maintained throughout production.

Strict Manufacturing Standard

The facility complies with established manufacturing standards, like DIN-2768-fine and DIN-2768-medium.

Advanced Testing Facilities

Completed prototypes go through various testing machines, like profile projectors, CMM, and 3D scanners.

Complete Quality Report

Get comprehensive quality reports from our in-house quality team or third-party labs.

Rapid-MFG Team

We provide exceptional support even after order completion, giving you the confidence to offer your products to your market. Expert technicians with over a decade of industry experience and vast product expertise assist you with troubleshooting and optimal product use.

Technical Support

Project Management