Get a Quote for Precision Aerospace&defence Parts

Receive prototypes and production parts that exceed the Aerospace&defence industry’s strict quality and safety standards. Our extensive capabilities include injection molding, 3D printing, and metal or plastic aerospace CNC machining.

Why work with us?

Producing parts for aerospace and defense applications requires suitable materials, manufacturing expertise, and adherence to strict regulatory requirements. No matter the end use of the region – commercial or defense application – Rapid-MFG can make your aerospace and defense parts possible.

Component design and engineering assistance

Our engineers and designers can assist with customizing and optimizing a 3D-printed or traditionally-manufactured component using an array of materials that best meets your needs.

High quality Aerospace&defence standards

Our engineers follow the universal AS9100 (BS EN 9100) quality management standard for the aerospace industry.

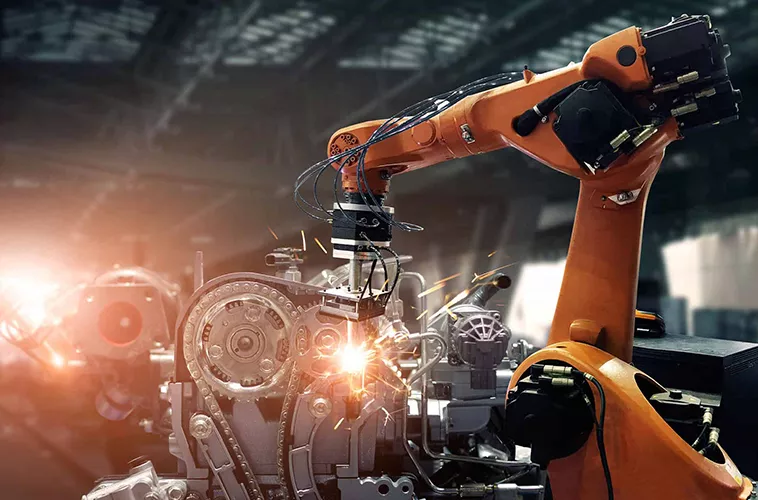

Advanced and traditional manufacturing of Aerospace&defence parts

Our facilities host a range of equipment to support both traditional manufacturing and additive manufacturing capabilities needed for complex assembly requirements and exacting specifications.

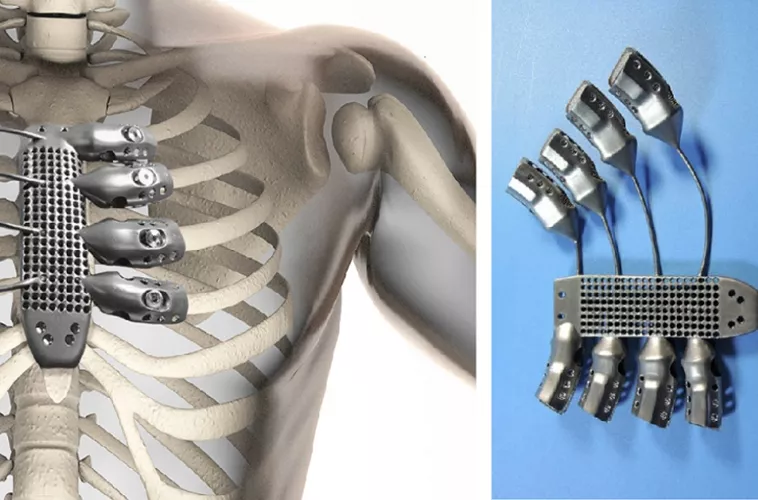

Provide high-quality parts processing solutions for the defense industry

Our professional design, machining, forming, and assembly teams and the latest component processing technologies enable aerospace and defense manufacturers to source the highest quality products to outperform competitors in demanding markets.

Parts manufactured for the defense industry require aesthetic expertise and stringent and specific requirements. Our machining processes and procedures ensure repeatability for each project. Rapid-MFG Quality Department takes careful consideration when validating documentation. With over 20 years in the business, you can rest assured that our team has extensive experience in aerospace engineering.

Quality Is Our Priority

Our quality program was developed and implemented by some of the most prestigious Quality Management personnel in the world! Rapid-MFG is in process of becoming AS9100:2016 certified to manufacture injection molded components for the Aerospace industry. Our documentation process ensures every detail, part callout, marking, and packaging requirement is met.

Aerospace Manufacturing Capabilities

Take advantage of our professional manufacturing services throughout the production cycle, from prototyping and design validation to functional testing and product launch. We deliver high-quality and precise flight-worthy components with fast turnaround and at low costs. With our quality control process, you can be sure of getting parts that meet your unique requirements.

Aerospace Applications

Our manufacturing capabilities help accelerate the production of a wide range of aerospace components for unique applications.

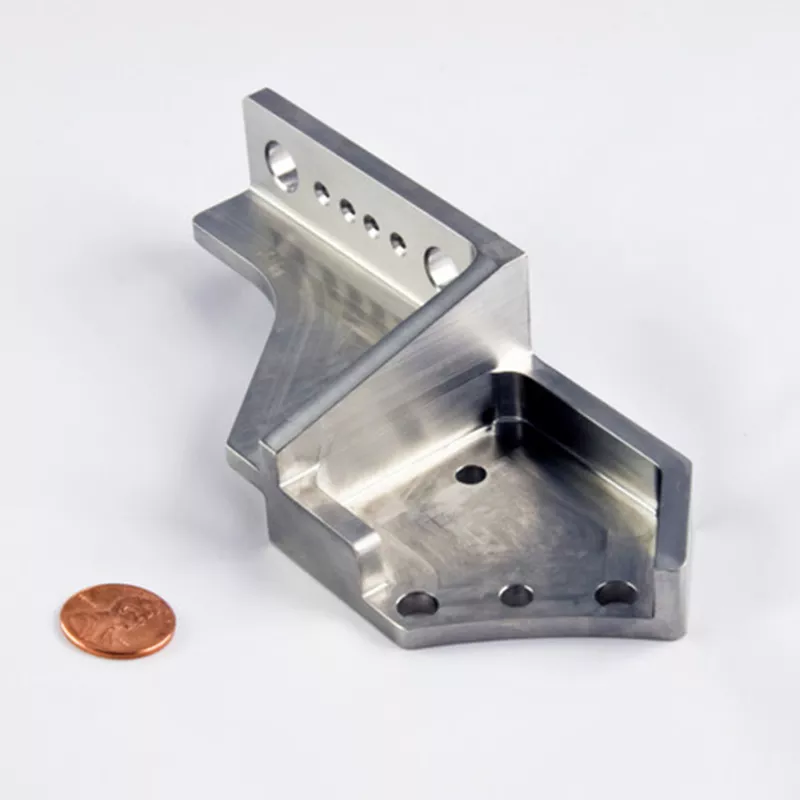

- Rapid tooling, brackets, chassis, and jigs

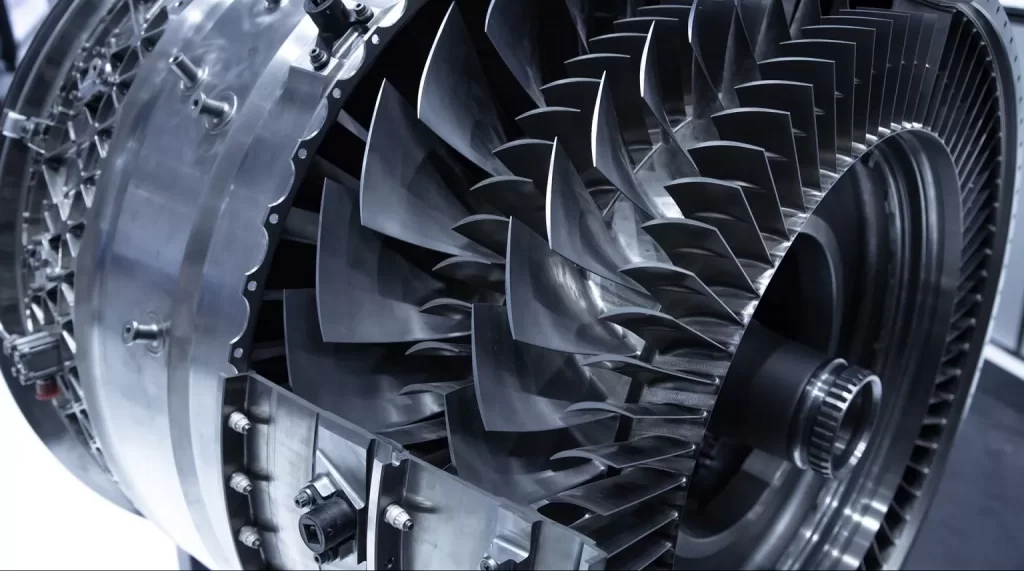

- Heat exchangers

- Custom fixturing

- Conformal cooling channels

- Turbo pumps and manifolds

- Fit check gauges

- Fuel nozzles

- Gas and liquid flow components

Explore More Industries We Support

Years of serving various clients gave us the experience and knowledge needed to support numerous industries.

Ready to make your parts with Rapid-MFG?

If you are a business in the aerospace or defence industry that is looking for high levels of communication, technical and precise injection moulding and the expertise to be able to offer advice backed by years of experience, then Rapid-MFG could be right for you and your business.

Check out the other industries we support

Advanced experience of German machine tools

Germany has long been recognized as a leading global producer of machine tools brought out by a combination of strong engineering

Large CNC Lathe Machining

Big bore CNC lathe is essential when manufacturing robust large parts and over size parts for a variety of applications which range from aerospace industry to equipment manufacturing.

Judging the accuracy of a CNC machining center

In the current environment in manufacturing, accuracy and precision in CNC machining centers are valuable commodities.