CNC milling is employed for greater precision, while CNC turning is chosen for higher efficiency.

What is CNC Milling?

CNC milling involves using a rotating cutting tool to remove material from a workpiece. The workpiece is typically held stationary on a table, while the cutting tool moves in multiple axes—usually along the X, Y, and Z axes. This process allows for the creation of complex shapes, slots, holes, and contours on various materials, including metals, plastics.

Key Characteristics of CNC Milling:

Multi-Axis Capability: CNC milling machines operate on multiple axes, enabling the creation of intricate designs and geometries.

Versatility: Suitable for a wide range of materials and part sizes, CNC milling is ideal for both prototypes and high-volume production.

Surface Finish: CNC milling often yields superior surface finishes, making it a preferred choice for parts that require a fine aesthetic or functional finish.

Let’s take a look at the finished product images of milling:

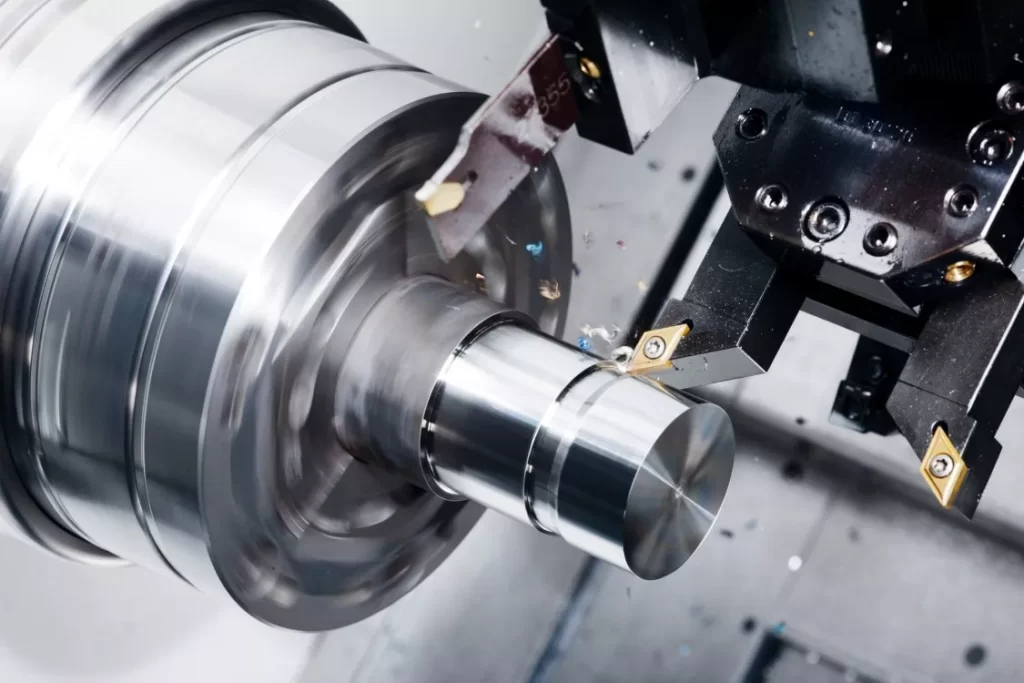

What is CNC Turning?

CNC turning, on the other hand, involves rotating the workpiece while a stationary cutting tool removes material. This process is typically used for creating cylindrical parts, such as shafts, bushings, and fittings. The workpiece is mounted on a spindle that rotates, allowing the cutting tool to move along the length of the part to shape it.

Key Characteristics of CNC Turning:

Cylindrical Parts: CNC turning is specifically designed for producing round or cylindrical shapes, making it the preferred method for such components.Speed and Efficiency: CNC turning can be faster than milling for certain applications, particularly for large production runs of similar parts.

Reduced Material Waste: The process often results in less waste, as the material is removed in a continuous manner.

When to Use CNC Milling vs. CNC Turning?

Choosing CNC Milling:

Use CNC milling when you need to create complex shapes, intricate details, or when the part requires features such as pockets, grooves, or angles.

It is ideal for flat surfaces or parts that require precise machining on multiple sides.

Choosing CNC Turning:

Opt for CNC turning when the primary requirement is to produce cylindrical shapes or when the part’s design is relatively simple with rotational symmetry.

It is best suited for high-volume production of similar components.

If CNC turning is possible, it should be the preferred choice. Milling should be chosen when there is a need for irregular shapes, as turning offers higher efficiency.Often, to ensure a more appropriate balance between efficiency and quality, a combination of CNC turning and milling is utilized.