Silicone Rubber Molding

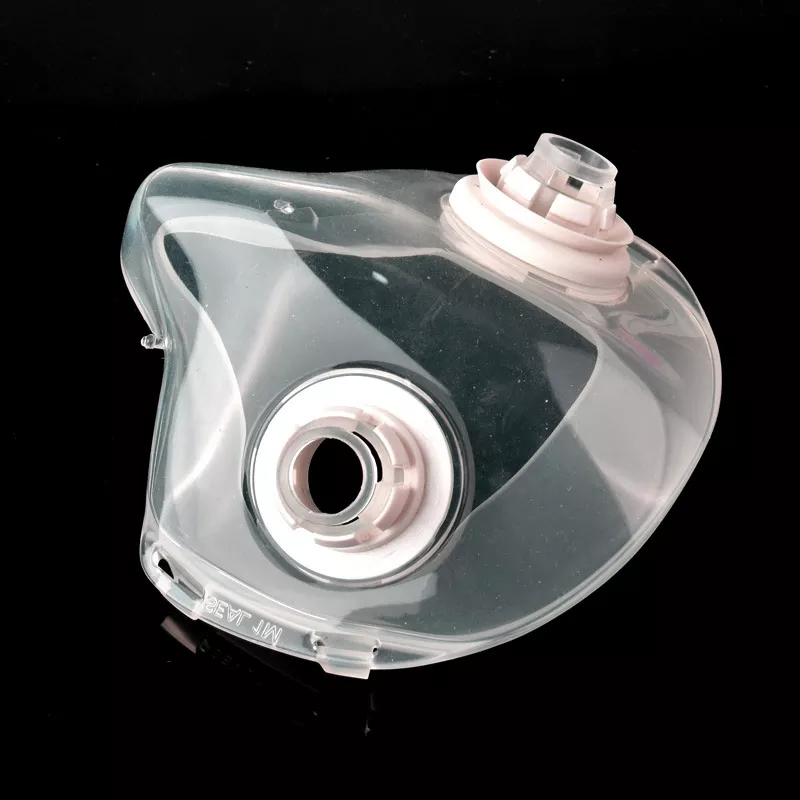

Producing your silicone rubber parts by silicone rubber moulding process.

Custom Silicone Rubber Molding Services

With a successful track record as a highly respected silicone rubber molding manufacturer, Rapid-MFG Silicone Rubber Molding has a long history of being a supplier of top-quality custom-molded products. We are equipped to handle a wide range of silicone rubber materials, from elastomers and silicone to neoprene, NBR, and EPDM. We adhere to precise tolerances of (±) 0.005 inch and specialize in the three most common rubber molding operations: compression, injection molding, and transfer.

Known for its extreme durability and elasticity, silicone rubber performs well in applications that require robust operation in high-pressure environments or under extreme deformation conditions. And with the ability to manufacture high-performance products composed of this durable material, we have been pleased to meet the needs of several industries, including aerospace, electronics, and medicine.

At Rapid-MFG, we are determined to provide our customers with superior products that meet the industry’s high standards. We invite you to contact Rapid-MFG to inquire about any of our additional service options, including rubber-to-metal bonding, anodizing, and rapid prototyping. From aircraft and mechanical components to custom seals and insulators, we offer superior custom silicone rubber molding products and services.

Types of Silicone Rubber Molding

We offer two different types of custom silicone molding: LIM (Liquid Silicone Injection Molding) and compression molding. What makes these two types different is the technology, process and machine that is used to mold the parts. While both processes are great options your part geometry and complexity will likely determine which process to use. Here is some more information on each process:

LIM Silicone molding:

Also known as LSR silicone molding (Liquid Silicone Rubber), this is a liquid injection molding process, where a high-viscosity liquid comes in two parts, Part A and Part B is loaded into the molding machine. The machine mixes the two parts just before it is injected into the mold cavity, where a chemical reaction causes it to cure very quickly. After the part is cured the part is either ejected or manually pulled from the mold.

Compression molding:

The process involves placing a silicone rubber sheet onto a heated mold cavity. The rubber sheet is compressed between the two mold halves and fills to the mold cavity due to heat and pressure. The part is allowed to cool and is removed from the mold. Compression molding has some distinct benefits including lower molding and manufacturing costs. This makes compression molding the ideal choice for parts with low to medium complexity such as o-rings and sealing gaskets.

Our silicone rubber molding Service

We are pleased to share decades of experience and silicone molding know-how with our customers to ensure that they receive only the highest quality silicone molded prototypes and production parts.

| Name | Description |

|---|---|

| Minimum order quantity | 100 runs |

| Mold material | Tool Steel P20 |

| Mold storage | Minimum 2 years |

| Mold lead time | Typically 1-2 weeks |

| Quality assurance | Inspection reports included, full dimensional report and material certifications available upon request. |

| Design verification program | Similar to First Article Inspection, you will receive 2 sets of parts upon the machining of the mold to test fit before continuing with full production. |

| Mold remachining | We can remachine the molds should any changes be required, changes to be reviewed on a case by case basis. |

| Reorders | Unit price is based on the quantity required for the reorder with an additional set up fee of $80- $200. |

| Additional technical support | Dedicated JunYi Mechanical Engineer for technical support. |

Advantages & Benefits of Using Silicone Rubber Molding

With faster time to market, faster, better iterations, and significantly lower project development costs, our custom silicone molding prototype service allows you to receive a quote quickly and have silicone parts and silicone prototypes swiftly made.

Flexible and Resilient

- Impact and drop protection

- Soft tactile feel (ergonomic)

- Great sealing performance

No taste or smell

- Inert material

- FDA and Medical grades available

- Used in food, medical industries

Great durability

- Good weather resistance

- Performs over wide temperature range

- Chemical resistance

Non-conductive

- Electrical insulator

- Available in UL certified materials

- Commonly used in electronics industry

Efficient silicone molding process

- Molding creates economical parts, fast

- Great for medium to high volume production

- Many options: durometer, finish, color

Why engineers use Rapid-MFG for silicone rubber molding

Instant Quotes and Fast DFM

We will provide prototype quotes on the same day. Usually, a section for tooling and production will be delivered within 48 hours. If you have plans to move forward with your project, we would like to provide a quick DFM for your reference free of charge.

Readily available capacity

Benefit from our high precision equipments, comprehensive manufacturing capability and dedicated team, we are standing by your side to get your projects move forward quickly.

Quality & reliability

Dedicated JunYi team to ensure your parts consistently meet your quality expectations. We also offer phone, email and chat support for any concerns or questions you may have.

We Work With Nearly All Industries

Rapid-MFG’s rubber molding services are ideally suited to address a variety of needs in different industries, including the automotive, medical and consumer goods sectors.

Request a Free Quote Today

Our facilities are equipped with state-of-the-art equipment and are managed using the latest technology. With production facilities located in China, we have the flexibility and ability to manufacture your parts efficiently and cost-effectively while meeting the highest quality standards.

Rapid-MFG’s custom rubber molding capabilities allow us to produce high quality products, providing you with solutions to your rubber part manufacturing challenges. Contact us today to find out how we can help.

silicone rubber molding news and industry updates

Advanced experience of German machine tools

Germany has long been recognized as a leading global producer of machine tools brought out by a combination of strong engineering

Large CNC Lathe Machining

Big bore CNC lathe is essential when manufacturing robust large parts and over size parts for a variety of applications which range from aerospace industry to equipment manufacturing.

Judging the accuracy of a CNC machining center

In the current environment in manufacturing, accuracy and precision in CNC machining centers are valuable commodities.